EXCELLENCE

Research & Development

|

Innovation and R&D Elite has successively completed the R&D and manufacturing of over 1,000 types of reducers, transfer cases, axles, PTO clutches and wet brakes. It has tackled more than 100 key technologies in the industry. It is one of the professional companies in China with professional R&D and large-scale manufacturing capabilities for power transmission products. |

|

R&D Strength – Ensuring Stable and Reliable Product Quality with High Technical Level Elite has built a R&D team led by senior industry experts with a complete professional structure. Among them, senior and intermediate engineers account for more than 50%. The company masters industry-leading design software for transmission products. It can independently complete the research and application of core technologies such as materials, forging, casting, heat treatment, machining, design, assembly and painting. It has 20 years of experience in OEM parts processing for foreign transmission products and has mastered advanced parts processing techniques. It guarantees the excellent quality of reducers, transfer cases, axles, PTO clutches and wet brakes through design and process technologies, ensuring stable and reliable product quality. |

|

|

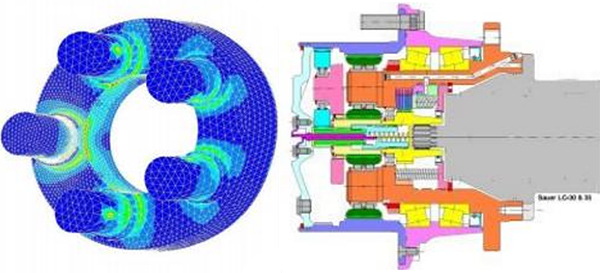

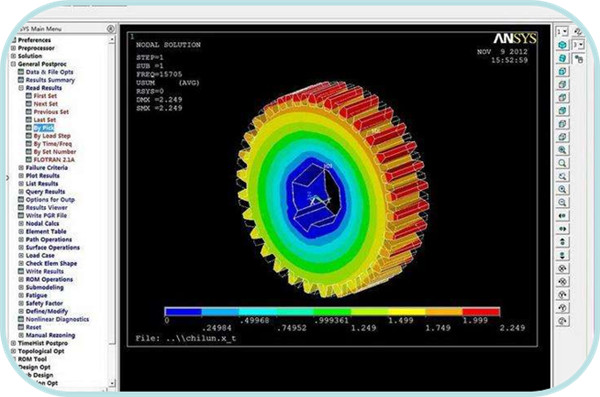

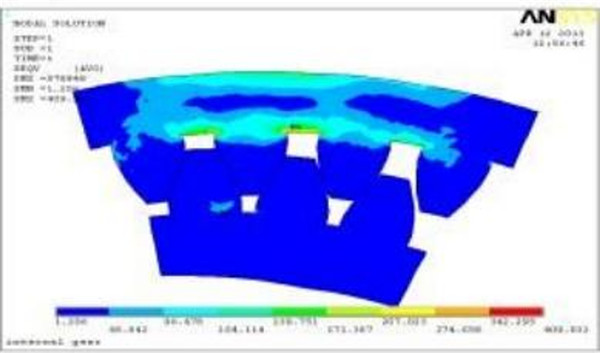

R&D Platform – Leading Design Technology Brings Leading Products Elite engineers use finite element analysis technology to analyze the full working condition stress and strength distribution of each component of power transmission products. They determine the load distribution form, establish a parameterized stress model of products simulating actual working conditions, and conduct product reliability design to ensure product quality. |

|

Exclusive Customization – Understanding Enough to Provide More Suitable Products We deeply understand the construction environment and service needs faced by customers. We use systematic professional knowledge for product design, verification and manufacturing to maximize customer needs. The company's new product R&D is based on the "Product Design and Development Control Procedure" and implements the requirements of the ISO9001 quality management system. It proceeds from product planning, project approval, scheme design, review, verification, confirmation, finalization and production to continuous improvement. All departments have clear responsibilities and work in an orderly manner, which not only ensures product quality, but also improves R&D efficiency and reduces R&D costs. |

|