EXCELLENCE

Manufacturing

Manufacturing at Elite covers assembly of customized and standard solutions, as well as advanced production of planetary gearboxes, pump drives, planetary axles, multiple disc brakes and power take-offs (PTO) clutches.

Excellence and innovation drive every process. This helps us provide customers with suitable products.

|

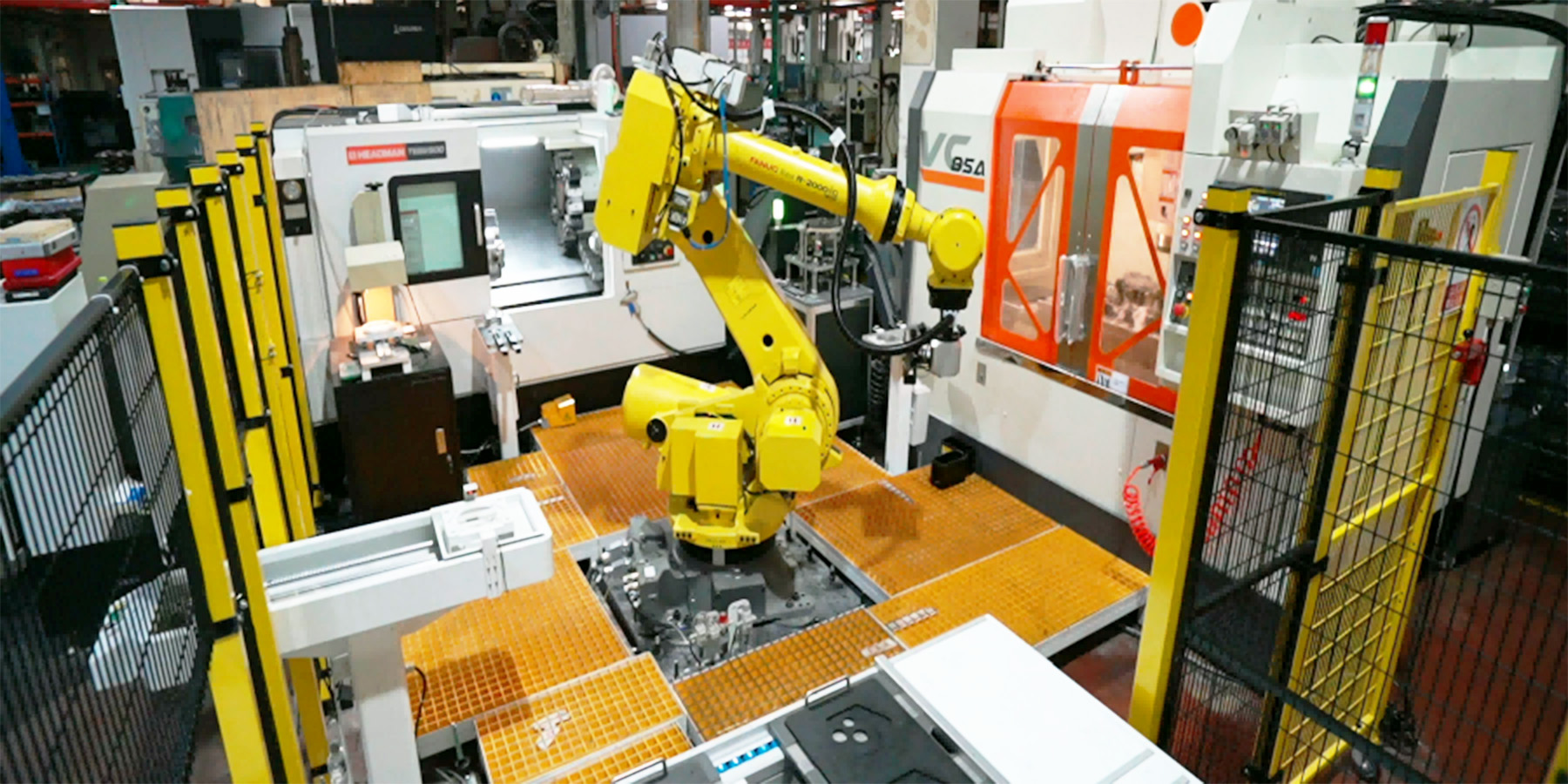

Advanced Equipment The company has over 200 imported high-precision processing machines. These include large CNC lathes, horizontal machining centers, gantry machining centers, CNC gear hobbing machines, CNC gear shaping machines, CNC gear grinding machines and large broaching machines. It has complete production capabilities. Key processes are all handled in-house, so part quality is controllable. |

|

Employee Team Elite has a production team with rich experience and a pursuit of excellence. Production staff make up 57% of total employees. Among them, technicians and senior technicians account for 12%. Such a high-quality production team strongly supports product efficiency and reliability. The company provides frequent, multi-dimensional internal training for employees. This ensures they keep improving their skills and quality awareness. In this way, full-process quality control of tracked undercarriages is achieved. |

|

|

Production Capacity Elite has a 100,000-square-meter factory. It also has 10 assembly lines. Its annual production capacity for drivetrain products can reach 100,000 units. |

|

|

CONTACT US

Wechat :+86 18661792179

No.63,Haier Road,Laoshan District Qingdao China

PRODUCTS

Didn't find what you were looking for?

Fill out the form below and we will be in touch as soon as possible.